In order for an engine to start rotating, it must develop an internal starting torque greater than the sum of the reaction moments;

that is, the moments of friction and payload.

The current required to generate the starting torque is much higher than the rated operating current of the motor.

The starting current for full load is IEK = 8.4 times the motor rated current Ion

Elevated starting currents can cause :

the sinking of the voltage network, Strong copper losses P Cu in the motor windings and hence thermal fatigue of the insulation tontyligmaton .

that is, the moments of friction and payload.

The current required to generate the starting torque is much higher than the rated operating current of the motor.

The starting current for full load is IEK = 8.4 times the motor rated current Ion

Elevated starting currents can cause :

the sinking of the voltage network, Strong copper losses P Cu in the motor windings and hence thermal fatigue of the insulation tontyligmaton .

At the start we are interested in 2 quantities:

a) the starting torque b) the starting current

The aim is to have as small a starting current as possible and a torque suitable for a smooth start.

Too much starting torque in relation to the load at start-up would give us a sharp start. Starting torque less than the load at start-up would not allow the engine to spin.

a) the starting torque b) the starting current

The aim is to have as small a starting current as possible and a torque suitable for a smooth start.

Too much starting torque in relation to the load at start-up would give us a sharp start. Starting torque less than the load at start-up would not allow the engine to spin.

The ways to start an asynchronous three-phase short-circuit motor are:

1. direct start at full mains voltage 2. start with star-delta switch 3. start with stator winding resistors 4. start with autotransformer 5. start with softst

1. direct start at full mains voltage 2. start with star-delta switch 3. start with stator winding resistors 4. start with autotransformer 5. start with softst

A device boot , ensures : Limitation of starting current to a safe value Limited voltage dip during startup (According DEI, should not exceed 5%). Starting torque required to start the load, with as little current as possible.

Direct start

In this method the motor is connected directly to the mains at full voltage. When the motor starts it will draw a large starting current (Ic) which can be 3-12 times greater than the normal ion operating current. That is, Iek = (3-12) * Ion. This method is ideal in case the initial starting current does not cause us problems and the initial starting torque is sufficient to start the engine.

In general, in Α.Τ.Κ.β.δ. their starting current or their peak current (Iek) is a multiple of their rated current (IN) depending on the motor characterization in terms of the number of poles, we assume that the following table shows the data:

The exact calculation of the starting current or peak current (IA) of Α.Τ.Κ.β.δ., results from their starting coefficient (k) - which is given to their technical characteristics by their manufacturer - on the nominal their current (IN), ie: Iek = k. IN

The limits of the maximum demand of the starting current set by PPC in relation to the number of starts of the motor concern the type of low voltage network (XT) that supplies the installation, that is, whether it is aerial or underground. These limits are given in the table below:

In case the consumer has his own substation, then the limit of the allowed starting current set by PPC , depends on the apparent power (KVA) of the private substation. These limits are given in the following table:

If none of the above is observed we should limit the starting current in one of the following ways:

With this switch the engine is started with reduced voltage in the windings and with star connection and then shortly before the engine reaches the nominal number of revolutions a triangle connection is made.

more about the star-delta circuit breaker can be found here

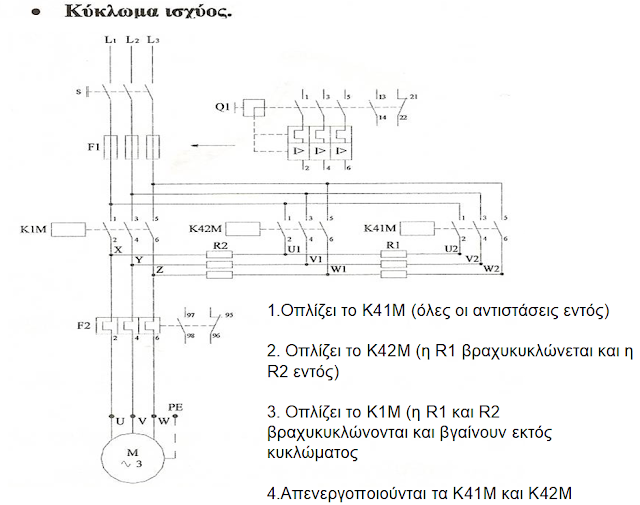

Start with stator resistors

Connect appropriate resistors in series with the stator winding. The motor starts with reduced voltage and as the speed increases we gradually reduce the resistance until it is all off.

Obviously with this method we have a reduction in starting current but reduced torque at start-up.

Therefore, this starting method is suitable only for low power engines and for cases where the increased measure of starting torque Tech.

Therefore, this starting method is suitable only for low power engines and for cases where the increased measure of starting torque Tech.

Start with autotransformer

The start with autotransformer is achieved by gradually increasing the supply voltage to the nominal one, where the autotransformer is also put out of circuit. This method allows us to have a slightly higher starting torque than when starting with stator resistors.

It consists of a single winding

It has an intermediate shot which determines how many coils the secondary winding will have

The Low Voltage (LV) winding is essentially a part of the High Voltage (LV) winding. This wrapping is called a common wrapping

The rest of the YT winding is called series winding

The load current is greater than the current flowing through the autotransformer secondary

With the autotransformer, the full voltage is supplied in stages (while in the start with stator resistors the full voltage is provided in 3 stages) after the motor has reached its nominal speed. Then disconnect the autotransformer via the dual power switch D1 and connect it to the motor directly to the mains for normal operation.

If an autotransformer is used for starting, the starting current is reduced by k 2 times, compared to the current in the case of direct starting, where k = the transfer ratio to the autotransformer.

However, you also reduce the starting torque by k 2 times, compared to the current in the case of direct starting.

Therefore, this method can only be used on loads that do not require increased torque at start-up. Otherwise, the engine will not start.

Traditionally, star/delta starters and autotransformers have been the solution to these high current problems when starting motors.

Both of these solutions, however, have drawbacks and do not solve the problems caused by wear on parts of the transmission system because they do not eliminate the risk of a sudden change in torque when the voltage changes resulting in unstable operating conditions

Both of these solutions, however, have drawbacks and do not solve the problems caused by wear on parts of the transmission system because they do not eliminate the risk of a sudden change in torque when the voltage changes resulting in unstable operating conditions

The star/triangle starter reduces the starting current but causes a catastrophic peak in torque when changing the connection from star to delta.

It does not allow the selection of the optimal starting current level, which sometimes means that the load cannot accelerate to the maximum speed in a triangle connection, which makes the star/delta starter inefficient.

In addition, it has no effect on the way the engine stops, thus allowing its speed to be reduced without any control

It does not allow the selection of the optimal starting current level, which sometimes means that the load cannot accelerate to the maximum speed in a triangle connection, which makes the star/delta starter inefficient.

In addition, it has no effect on the way the engine stops, thus allowing its speed to be reduced without any control

The autotransformer reduces the starting current but also allows some control over the starting current level. Autotransformer starters, however, do not eliminate the risk of a sudden change in torque when the voltage changes.

There are many cases where we are not interested in controlling the speed of a three-phase short-circuit motor, so we do not need an "expensive" inverter, but we also do not want, mainly for cost reasons, to run 7 wires, use three relays, plus time, for implementation of triangle star start automation.

In this case, there is the alternative of using a "cheap" smooth starter or soft starter.

The electronic voltage regulator or soft starter is one of the most modern and reliable electronic motor control devices

In this case, there is the alternative of using a "cheap" smooth starter or soft starter.

The electronic voltage regulator or soft starter is one of the most modern and reliable electronic motor control devices

It is suitable for controlled smooth starting but also stopping for braking and energy saving during the operation of three-phase asynchronous motors.

more about soft starters can be seen here

Watch a video with different ways to start

https://www.youtube.com/watch?time_continue=243&v=O_qxHYzB_f0 https://gr.pinterest.com/pin/299770918923874801/https://gr.pinterest.com/pin/105060603788279408/

Automatic start asynchronous three-phase motor

To thank the ELECTRICIANS of the 1st EPAS OAED THESSALONIKI for the amazing technological content and the wonderful articles they publish on their blog.